Problem Statement

Manufacturing companies fabricate products to satisfy customers’ needs. Preceding fabrication, the product needs to be developed; this is known as the product development process. From a general point of view, this process covers:

- product requirements;

- product conceptualization;

- product design;

- product analysis and optimization; and

- production planning.

This process can also be strengthened by high-end software solutions (i.e. computer-aided technology – CAx). Big manufacturing companies operate CAx systems to accelerate the development process, to reduce the associated costs, and to improve the time to market. Nonetheless, the CAx systems are very expensive to acquire and these are normally based on annual license fees; even if the corresponding CAx system is just used a few times a year. Many of these systems require very powerful hardware resources (high-performance computing – HPC), which are even less affordable. Besides the cost-intensive bare machines (HPC equipment), it requires skilled experts to operate the equipment and to effectively configure the CAx systems.

Furthermore, the digital development of a product does not require just one CAx system; but typically in engineering workflows, many different software components from various providers are needed; e.g. car makers use up to 170 simulation tools alone (verbal communication with Audi AG). As a consequence, small companies need to wait long periods of time for just one simulation, being forced to continue working with physical prototypes and trial-and-error cycles, which are also time and cost demanding.

A first approach to mitigate this problem was the proliferation of engineering offices, offering their services with high expertise in specific software solutions. Nevertheless, this can become a severe bottleneck and an expensive process depending on the needed design iterations, and it does not resolve the integration issues across different service providers. As a result, especially small and medium-sized enterprises (SMEs) cannot afford to use state-of-the-art technology, including simulation tools and HPC hardware in their development process; and thus, not being able to fully exploit their potential competitiveness, time-to-market, and innovation capabilities.

With the progress of information technology, some software vendors are starting to explore new services based on cloud computing (i.e. Internet-based processing resources) along with new business models (e.g. pay-per-use or pay-as-you-go). Although, this approach might be a relief for the customers, this is still experimental and the representation of workflows bridging different software tools remains a challenge.

Nowadays, Internet portals are starting to provide different cloud-based software tools; however, those portals do not allow for configuring the tools according to typical design, engineering and manufacturing workflows. This generates interoperability issues between the independent end results and it also causes delays because of the required upload and download of data for the individual tools.

Even though computing clusters and cloud software are somewhat available, small companies might not have the know-how to set up and run the needed engineering computations. Hence, there still is a need for a holistic solution, a solution with flexible, scalable, and cost-effective cloud engineering services, and with expertise in the software tools and in the engineering principles.

Customer’s Perspective

A manufacturing SME is in the process of developing the next version of a product; the product should perform the same functionality as before, but it should be innovative, by considering:

- shape variations;

- different materials; and

- alternative fabrication methods.

This innovation should translate into lower carbon footprint and fabrication costs, higher quality and recyclability, as well as optimized efficiency and economic value. In order to achieve this, the SME would like to boost the product development process by means of integrating multiple CAx computations. Nevertheless, the SME does not have the financial resources to buy the software licenses, to acquire powerful computers, or to pay for the engineering expertise. The SME could indeed benefit from new business models to access such CAx systems on-demand and without the need for special equipment.

Following this line of motivation, the SME should be enabled to employ a standard mechanism (e.g. an Internet browser) with an easy registration process and a simple interface, facilitating the selection of the desired computations, the provision of the required input parameters, and the analysis of the generated results. Likewise, the SME should also have access to expert support upon request, in view of understanding and preparing the engineering solution, or in view of using and setting up the CAx computations.

As a results, the SME will be capable of fostering its innovation without jeopardizing its liquidity, while strengthening its competitiveness and added value, and improving the likelihood to increase its customer base. In return, the SME will profit from solid finances, allowing it to recruit new employees, to further grow, and to cover the increasing demand.

Solution

clesgo wants to become the single point of access for any cloud-based engineering service, supporting the customers with expert knowledge and empowering them to execute digital manufacturing workflows. clesgo will empower the customers to get the maximum possible profit from the technology for their individual needs and requirements. clesgo’s promise to the customer will be:

- empowering customers in accessing high-end engineering services on-demand;

- streamlining the engineering development by using flexible and elastic computing resources;

- enabling customers to create chains of services representing engineering processes;

- integrating new service providers for the benefit of the customers; and

- promoting the understanding and usage of cloud-based engineering services.

clesgo’s promise is also reflected in its organizational structure. On the one hand, the customer development aspect is completely focused on understanding and providing the best possible experience to the customer. On the other hand, the business innovation aspect analyses the customers and their surroundings, in order to define innovation roadmaps that generate added-value in the processes externally within the customers’ premises and internally within clesgo.

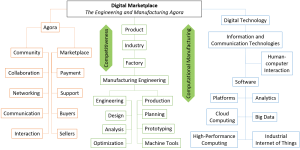

In order to achieve this purpose, clesgo will provide a Digital Marketplace, featuring a uniform and streamlined interface that abstracts the different cloud engineering services. By means of the Digital Marketplace, the customer will get familiar with a single interface and will be able to configure and operate the services regardless of the providers (existing or upcoming ones). For specialized workflows, the customer will be able to access the individual interface of the corresponding Engineering App.